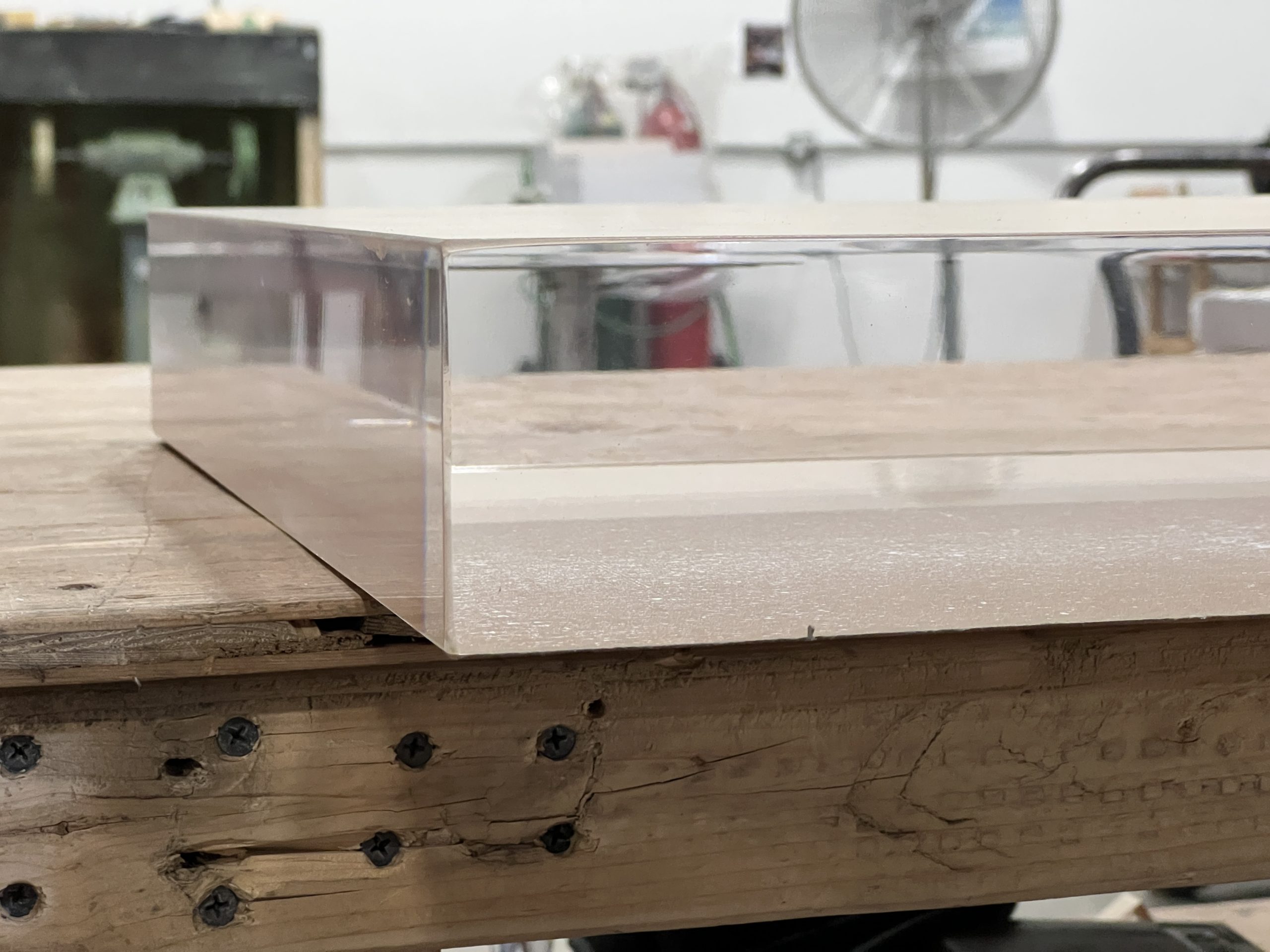

Polishing Acrylic Edges

When acrylic is cut mechanically, it often has rough edges, which is ok for applications where edges are not exposed. However, for a finer, finished look to the plastics edge, many customers opt for a polished refined look. This is very popular when the plastic is being used as a stand-alone show piece.

Beyond saw cutting there are a few ways to polish acrylic. Flame polishing uses an 800-degree flame to instantly polish the cut edge. This produces a nice shiny finish, but the flame polished edge is more sensitive to cleaners, sometimes causing stress marks called crazing.

The best polishing method is a manual process using a combination of diamond edge polishing machines and then hand buffing the edges, yielding a smooth, flawless finish with great optical clarity.

Most recently the Acrilex fabrication team cut and polished these 3” thick acrylic blocks to be used in a high-end retail store as display risers.

Acrilex fabrication is ready to take on your project. Ask us today how we can save you time and money.

Contact us for a quote at acrilex@acrilex.com.